Lean Manufacturing Digitization: Complete Guide to Lean 4.0

Introduction

Manufacturers worldwide are adopting Lean Manufacturing Digitization to reduce waste, improve productivity, and gain real-time process visibility. Traditional Lean tools like 5S, VSM, or Kaizen rely heavily on manual observation. But in today’s high-speed production environment, manual data is slow, inconsistent, and often inaccurate.

Digitization gives Lean a powerful upgrade — enabling real-time data, automated monitoring, predictive insights, and faster decision-making.

This blog explores how to integrate Lean principles with digital technology to achieve Lean 4.0.

What is Lean Manufacturing Digitization?

Lean Manufacturing Digitization means combining Lean principles with digital technologies to:

- Improve efficiency

- Reduce human error

- Visualize waste instantly

- Automate repetitive tasks

- Enable real-time monitoring

It is NOT replacing Lean.

It is enhancing Lean with accurate data and smart automation.

Why Digitization is Essential for Lean

Manufacturing complexity has increased, and companies need faster insights. Lean without digital tools often fails due to:

- Delayed data collection

- Wrong cycle time measurements

- Hidden downtime

- Lack of traceability

- Human errors in reporting

How Digitization Solves Lean Challenges

| Lean Problem | Digital Solution |

| Manual OEE calculation | Automated OEE dashboards |

| No real-time visibility | IoT sensors + live monitoring |

| Poor traceability | RFID, barcode systems |

| Delay in problem escalation | Digital Andon alerts |

| Slow audits | Mobile-based digital checklists |

How Digitization Enhances Lean Tools

1. Digital 5S

- QR codes for location identification

- Photo-based digital 5S audits

- Auto-scoring for workplace conditions

2. Digital Value Stream Mapping (VSM)

- Software for real-time VSM

- Automatic cycle/takt time updates

- Cloud-based process flow monitoring

3. Digital Gemba Walk

- Mobile-based audit checklists

- Instant issue capturing with photos/videos

- Live escalation to supervisors

4. Digital Standard Work

- Digital SOPs available on tablets

- Video work instructions

- Automatic deviation alerts

5. IoT-Enabled Machine Monitoring

- Real-time OEE

- Downtime classification

- Predictive maintenance using sensor data

6. Electronic Kanban (E-Kanban)

- Auto-replenishment triggers

- RFID/barcode tracking

- Inventory level live monitoring

Digitization and the 8 Wastes of Lean

Digitization eliminates waste faster and more accurately.

| Lean Waste | How Digitization Helps |

| Overproduction | AI forecasting, WIP tracking |

| Waiting | Downtime alerts, auto scheduling |

| Transportation | Layout simulation tools |

| Overprocessing | Digital instructions reduce errors |

| Inventory | E-Kanban, live stock updates |

| Motion | QR search reduces walking/search time |

| Defects | Digital QC, inline sensors |

| Underutilized Talent | Automation frees time for Kaizen |

Digital Tools Used in Lean Manufacturing

Software Tools

- OEE Monitoring System

- Digital Maintenance (CMMS)

- ERP/MES Systems

- Digital VSM tools

- Workflow automation software

Hardware Tools

- IoT sensors

- Tablets and kiosks

- Barcode/RFID readers

- Andon lights and digital panels

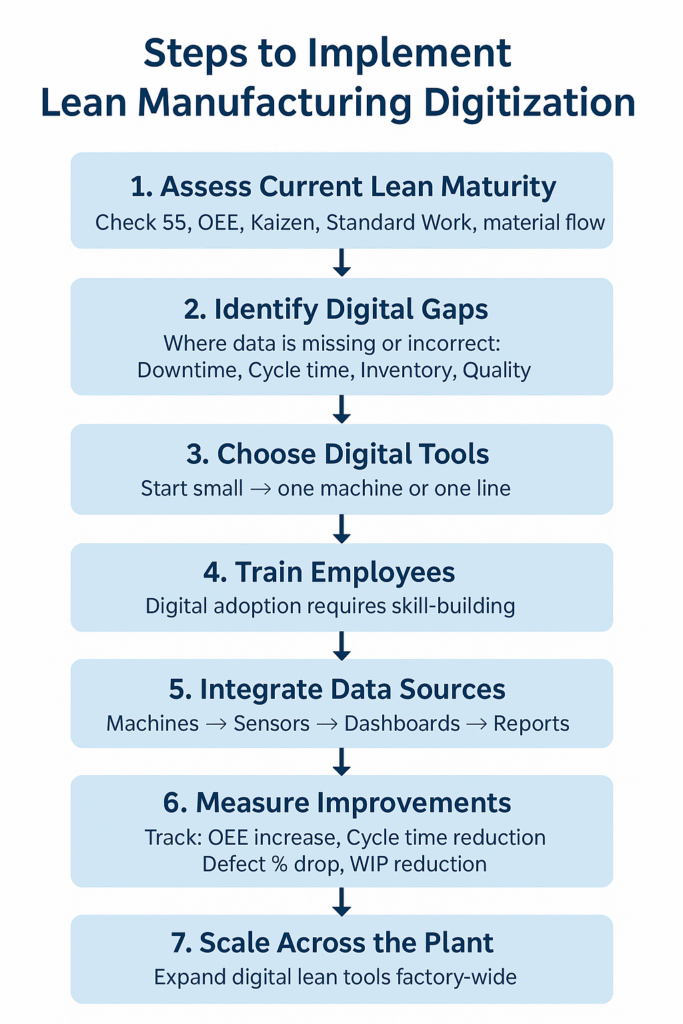

Steps to Implement Lean Manufacturing Digitization

1. Assess Current Lean Maturity

Check 5S, OEE, Kaizen, Standard Work, material flow.

2. Identify Digital Gaps

Where data is missing or incorrect:

- Downtime

- Cycle time

- Inventory

- Quality

3. Choose Digital Tools

Start small → one machine or one line.

4. Train Employees

Digital adoption requires skill-building.

5. Integrate Data Sources

Machines → Sensors → Dashboards → Reports.

6. Measure Improvements

Track:

- OEE increase

- Cycle time reduction

- Defect % drop

- WIP reduction

7. Scale Across the Plant

Expand digital lean tools factory-wide.

Case Study Example

A precision engineering company implemented:

- IoT machine monitoring

- Digital 5S audits

- E-Kanban system

Results in 4 months:

- 20% increase in OEE

- 30% reduction in breakdowns

- 25% reduction in WIP

- 40% faster response to issues

Common Challenges and Solutions

| Challenge | Solution |

| Employee resistance | Training + involvement |

| High cost | Start with pilot project |

| Too much data | Focus on key KPIs |

| System integration | Choose scalable digital platforms |

Conclusion

Digitization and Lean together deliver Lean 4.0—a smarter, faster, and more efficient manufacturing environment. While Lean provides the philosophy, digitization provides the real-time data and automation required to achieve world-class performance.

Companies that adopt Lean Digitization achieve:

- Higher productivity

- Lower costs

- Faster problem-solving

- Better quality

- Stronger customer satisfaction

FAQs About Lean Manufacturing Digitization

1. What is Lean 4.0?

Lean 4.0 integrates Lean principles with Industry 4.0 technologies like IoT, automation, and AI.

2. Is digitization expensive?

Not necessarily. Start with small pilots like digital checklists or OEE monitoring.

3. Can digital tools replace Lean?

No. Digital tools enhance Lean but do not replace its principles.

4. What is the fastest way to start digital Lean?

- “What is OEE and How to Improve It?”

- “Step-by-Step Guide to Identifying Lean Opportunities”

- “Industry 4.0 Tools for Manufacturing”

- “How to Reduce Machine Downtime Using IoT”